**Product Introduction**

Split plummer blocks are designed with a separable cap and base, making them ideal for bearing radial loads. These units are compatible with self-aligning spherical roller bearings or self-aligning ball bearings, and they are widely used in industries such as metallurgy, mining, conveyor systems, and environmental protection. The main model series include SN, SD, SNU, SNL, 1500, 1600, Z2500Y, Z2600Y, GZ2, GZ4, and more. The key differences between models lie in their load capacity and sealing types (such as oil felt, TG, U-lock, TS). These blocks offer excellent heat dissipation, simplify installation and removal procedures, and enhance sealing efficiency.

**Specifications**

- **Model No.:** SN505, SN506, SN507, ..., SN532

- **Material:** Cast iron, Ductile iron, Cast steel

- **Standards:** GB/T 7813-1998, ISO 113:1

**Technical Parameters**

| Housing No. | Shaft Dia. (d1) | Dimensions (mm) | Bearing No. | Adapter Sleeve | Locating Ring | Weight (kg) |

|-------------|------------------|------------------|--------------|----------------|----------------|-------------|

| SN505 | 20 | 52 x 165 | 1205K | M12 | 15 | 4.2 |

| SN506 | 25 | 62 x 185 | 1206K | M12 | 15 | 5.4 |

| SN507 | 30 | 72 x 185 | 1207K | M12 | 15 | 5.4 |

| SN508 | 35 | 80 x 205 | 1208K | M12 | 15 | 5.4 |

| SN509 | 40 | 85 x 205 | 1209K | M12 | 15 | 5.4 |

| SN510 | 45 | 90 x 205 | 1210K | M12 | 15 | 5.4 |

| SN511 | 50 | 100 x 255 | 1211K | M16 | 18 | 6.9 |

| SN512 | 55 | 110 x 255 | 1212K | M16 | 18 | 6.9 |

| SN513 | 60 | 120 x 275 | 1213K | M16 | 18 | 6.8 |

| SN515 | 65 | 130 x 280 | 1215K | M16 | 18 | 6.8 |

| SN516 | 70 | 140 x 315 | 1216K | M20 | 22 | 8.1 |

| SN517 | 75 | 150 x 320 | 1217K | M20 | 22 | 8.1 |

| SN518 | 80 | 160 x 345 | 1218K | M20 | 22 | 8.1 |

| SN519 | 85 | 170 x 345 | 1219K | M20 | 22 | 8.1 |

| SN520 | 90 | 180 x 380 | 1220K | M24 | 26 | 9.3 |

| SN522 | 100 | 200 x 410 | 1222K | M24 | 26 | 10.8 |

| SN524 | 110 | 215 x 410 | 1224K | M24 | 26 | 10.7 |

| SN526 | 115 | 230 x 445 | 1226K | M24 | 28 | 10.7 |

| SN528 | 125 | 250 x 500 | 1228K | M30 | 33 | 12.2 |

| SN530 | 135 | 270 x 530 | 1230K | M30 | 33 | 12.2 |

| SN532 | 140 | 290 x 550 | 1232K | M30 | 33 | 13.7 |

These split plummer blocks are designed to meet high-performance standards while ensuring ease of maintenance and long service life. They are available in various sizes and configurations to suit different industrial applications. Whether you're working in heavy machinery, conveyor belts, or precision equipment, these blocks provide reliable support and durability.

Pneumatic Cylinder Accessories

Pneumatic air cylinder accessories mainly include cylinder mounting brackets, piston rod connecting joints, repair sealing parts, magnetic reed switch, as well as cylinder assembly kits and cylinder barrels, piston rods etc.Air Cylinder Tube.

Air cylinder accessories of different models and different standards are generally not interchanged. When ordering Pneumatic Cylinder accessories, please note the specifications and parameters of the corresponding cylinder. If the standard and model of the cylinder are same, the cylinder accessories can be used interchangeably.Pneumatic Cylinder Tube.

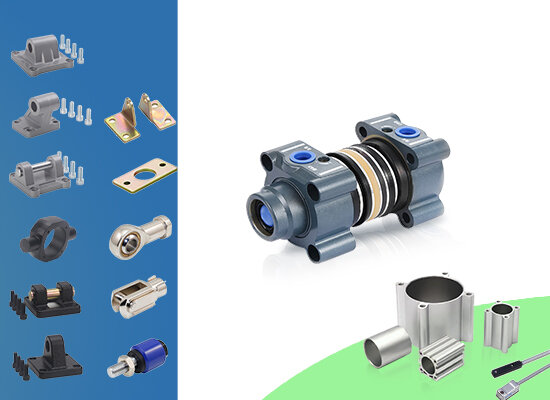

Pneumatic cylinder is the executing component in pneumatic systems, mainly used to convert the pressure energy of compressed air into mechanical energy, generating linear or oscillatory motion. The construction of pneumatic cylinders is complex and includes multiple key components. Below are some common components and their functions:

Cylinder Barrel: This is the main body of a cylinder, typically a cylindrical container used to accommodate pistons and other internal components. The cylinder barrel must be strong enough to withstand the pressure of compressed air inside.

Piston: located inside the cylinder and in close contact with the inner wall of the cylinder barrel. When compressed air enters the cylinder, the piston moves inside the cylinder barrel, generating thrust or tension.

Piston Rod: The part that connects the piston to the external mechanical structure and is used to transmit the linear motion of the piston.

End caps/caps: fixed at both ends of the cylinder barrel, sealing the internal space of the cylinder and supporting the piston rod and other components. The front cover usually includes a guiding component for the piston rod.

Seals: Used to prevent gas leakage and ensure smooth movement of the piston within the cylinder barrel. It mainly includes piston sealing rings, rod sealing rings, and dust sealing rings.

Guide bushing: Helps the piston rod maintain the correct direction of movement, reducing friction and wear.

Buffer Device: Some cylinders are equipped with buffer devices to slow down the speed of piston movement when it reaches the end point, preventing impact and noise.

Magnetic switches: Some cylinders have built-in or external magnetic switches used to detect the position of the piston and control the action of the cylinder.

Exhaust Flow Control Valve: Sometimes integrated into the cylinder, it is used to regulate the exhaust speed and control the speed of the piston.

These components work together to enable the pneumatic cylinder to effectively convert the energy of compressed air into the required mechanical motion. According to specific application requirements, pneumatic cylinders may also include other specially designed components to meet specific functional requirements.

Pneumatic Cylinder Accessories,Pneumatic Cylinder Parts

Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com