Introduction

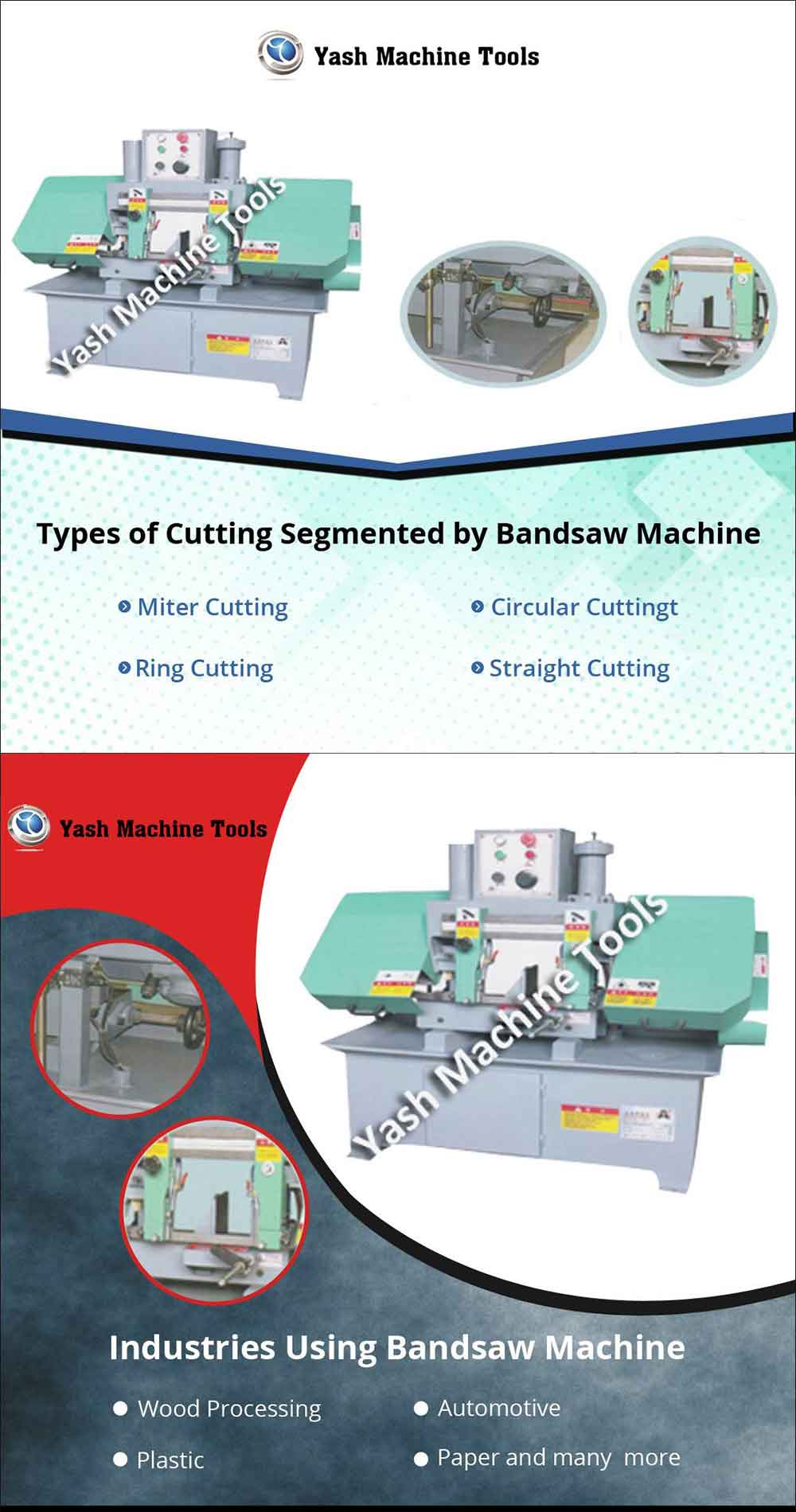

Bandsaw machines are an essential tool in today’s workshops, representing the evolution of cutting technology. With a focus on accuracy, efficiency, and adaptability, they have quickly become a preferred choice over traditional methods. Whether you're working with wood, metal, or other materials, bandsaws offer precision that is hard to match.Types of Bandsaw Machines

There are several types of bandsaw machines, each designed for specific tasks and materials:Horizontal Bandsaw

Horizontal bandsaws are ideal for making straight cuts on large or heavy workpieces. Their design allows for easier handling of thick materials, making them popular in metalworking shops where durability and strength are key.Vertical Bandsaw

Vertical bandsaws, on the other hand, are perfect for intricate curved cuts. They feature a blade that moves upward, allowing for detailed shaping and carving, especially in woodworking projects where precision is crucial.Dual Column Bandsaw

Dual column bandsaws combine the advantages of both horizontal and vertical models. This makes them highly versatile, suitable for both straight and curved cuts, and ideal for workshops that handle a variety of materials and tasks.Key Components and How They Work

Understanding the components of a bandsaw machine helps in appreciating how it functions. The blade, motor, table, blade guides, and tension system all work together to ensure smooth and accurate cuts. Proper maintenance of these parts is essential for optimal performance.Applications in Woodworking

In woodworking, bandsaw machines are used for a wide range of tasks, including resawing, cutting curves, and making precise crosscuts. Their ability to handle different wood types and thicknesses makes them a favorite among carpenters and woodworkers.Applications in Metalworking

In metalworking, bandsaw machines excel at cutting through various metals such as steel, aluminum, and brass. Their ability to handle tough materials without excessive wear makes them a reliable tool in manufacturing and fabrication settings.

Advantages Over Other Cutting Tools

Compared to other cutting tools, bandsaw machines offer greater precision, reduced material waste, and improved efficiency. Their versatility across different materials makes them a top choice for professionals looking for reliable and flexible cutting solutions.How to Choose the Right Bandsaw Machine

Selecting the right bandsaw depends on your specific needs. Consider the type of material you'll be cutting, the size of the workpieces, and any additional features like digital controls or automated systems. Choosing wisely ensures better performance and longer machine life.Maintenance Tips for Longevity

Regular maintenance is key to keeping your bandsaw in top condition. This includes cleaning the blade, lubricating moving parts, and checking the tension system. Proper care not only extends the life of the machine but also improves its performance and safety.Safety First: Important Precautions

Safety should always be a priority when using a bandsaw. Always follow manufacturer guidelines, use proper protective gear like gloves and goggles, and make sure all safety guards are in place before starting the machine.Recent Technological Innovations

Modern bandsaw machines are increasingly incorporating advanced technologies such as digital control panels, automation features, and smart sensors. These innovations improve accuracy, reduce operator fatigue, and enhance overall efficiency.Bandsaws in Artistic Creations

Beyond industrial use, bandsaws are also widely used in artistic fields. Sculptors, woodcarvers, and artists rely on these machines to create complex shapes and designs with high precision. Their flexibility makes them a valuable tool for creative expression.Environmental Considerations

As sustainability becomes more important, bandsaw manufacturers are focusing on energy-efficient models and recyclable components. These eco-friendly designs help reduce the environmental impact of cutting operations.

The Future of Bandsaw Technology

Looking ahead, bandsaw technology is expected to evolve even further. Integration with AI, IoT, and smart systems could revolutionize how these machines operate, making them even more efficient and user-friendly.Conclusion

In summary, bandsaw machines have become a vital part of the cutting industry due to their precision, efficiency, and versatility. As technology continues to advance, these tools will remain at the forefront of innovation, helping shape the future of manufacturing and craftsmanship.Frequently Asked Questions (FAQs)

Are bandsaw machines suitable for both wood and metal?

Yes, bandsaw machines are designed to handle a wide range of materials, including wood, metal, plastics, and more. Their versatility makes them a great choice for different industries.

What safety measures should I take when using a bandsaw?

Always read the manual, wear appropriate safety gear, and keep the machine well-maintained. Make sure to use blade guards and avoid distractions while operating the machine.

Can bandsaws be used for artistic purposes?

Absolutely! Many artists and sculptors use bandsaws to create intricate designs and custom pieces. Their precision and adaptability make them ideal for creative projects.

How do I choose the right bandsaw for my workshop?

Consider the type of work you’ll be doing, the size of the materials, and the level of automation or control you need. Consulting with experts can also help you make the best decision.

What new developments are coming in bandsaw technology?

New advancements include smart controls, automated blade tensioning, and integration with digital design software. These improvements aim to increase efficiency and ease of use for operators.

Noodle & Water Shooter Series,Seahorse Water Shooter,Water Noodle With Animal Heads,Water Gun Shooter

ZHOUSHAN SKYTOP COMMODITY CO., LTD. , https://www.bodyboard.com.cn